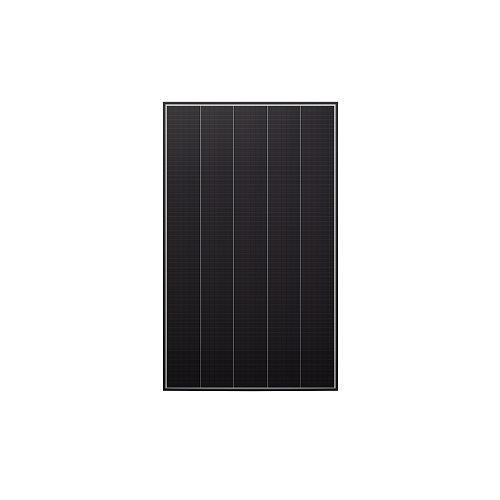

Black Frame Shingled Monocrystalline PV Solar Module

Shingled modules are an innovative solar photovoltaic technology that uses laser slicing technology and conductive adhesive connections to realize stacked connection packaging of solar cells, creating a superior circuit connection effect with zero spacing between solar cells. It has significant advantages such as optimal circuit connection effect, higher energy density, and higher power generation performance. By reducing line losses and BOS investment costs for system-side owners, shingled modules become more competitive in the photovoltaic industry.

- Brand:SunEvo

- Power Range:400~430W

- Max. Efficiency:21.7%

- Number of Cells:305 (61 × 5)

- Dimensions of Module L*W*H:1812 × 1096 × 30mm

- Weight:20.8kg ± 0.3kg

- Front Side Glass:Tempered glass, 3.2mm

- Backsheet:EVA

- Frame:Anodized aluminum alloy

- Junction Box:IP68, two diodes

- Cable:4mm2 ,+300mm/-1000mm(Vertical), +220mm/-180mm(Horizontal)

- Wind/Snow Load:4500pa

- Connector:MC4

- Product categories

how can we help you

Description

SunEvo Black Frame Shingled Monocrystalline PV Solar Module Profile

Electrical Characteristics (STC*)

|

Maximum Power: Pmax [W]

|

430 | 425 | 420 | 415 | 410 | 405 | 400 |

|

Open Circuit Voltage: Voc [V]

|

41.8 | 41.7 | 41.6 | 41.5 | 41.4 | 41.3 | 41.2 |

|

Short Circuit Current: Isc [A]

|

13.05 | 13.03 | 12.92 | 12.80 | 12.65 | 12.53 | 12.41 |

|

Voltage at Maximum Power: Vmp [V]

|

34.7 | 34.6 | 34.5 | 34.4 | 34.4 | 34.3 | 34.2 |

|

Current at Maximum Power: Imp [A]

|

12.40 | 12.30 | 12.19 | 12.08 | 11.93 | 11.82 | 11.71 |

|

Module Efficiency: η [%]

|

21.7 | 21.4 | 21.1 | 20.9 | 20.6 | 20.4 | 20.1 |

Product Pictures

Feature

Shingling uses laser slicing technology to cut the entire battery into several battery strips and uses conductive adhesive to flexibly connect the stacked battery strips. This kind of operation can optimize the module structure and achieve zero cell spacing. The same layout can place 5% more cells than other types of modules, effectively increasing the light-receiving area of the module. The latest generation of high-efficiency shingling technology adopts battery surface optimization technology to improve current collection capabilities and can further increase the limit of component packaging energy density.

Advantage

1. Higher conversion efficiency

2. Better resistance to hot spots

3. Lower risk of cracking

4. Less impact from occlusion

5. Lower resistance

FAQ

- 1. What is the MOQ?

- Our MOQ is one pallet, 36pcs/pallet

- 2. What is the warranty?

- 25-year material warranty, 25-year power warranty

- 3. What is the lead time?

- 15 working days

- 4. What is the package?

-

36pcs/box; 924pcs/40’container

Related Tags:

Leave A Message

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Subject :